If you take care of industrial properties enough time, you know the distinction between a settlement deal concern as well as a sidewise action complication. Piece heaves, stair-step splits, as well as drooping light beams tell one tale. Bowed basement wall surfaces, bending escalator shafts, as well as preserving designs creeping towards a road tell one more. Helical tieback anchors stay in that second tale. They are the utility vehicle for withstanding sidewise loads where excavation is actually confined, dirts are weak, or even speed as well as gain access to restraints create conventional solutions impractical.

I knew this the hard way on a 1960s office complex with a brick front and a basement that available to a packing dock. The dock wall surface had been covered a dozen times. Every winter season the tuckpointing stopped working, and every spring season the wall structure pitched a bit extra. Digging deep into ten feet strong close to electricals and an active alley was actually a nonstarter. Helical tieback anchors solved it precisely: very little interruption, an expected ability, and also a service warranty I might stand behind. Ever since, I try to find helical tiebacks whenever sidewise restraint is actually the regulating issue during the course of business groundwork stabilization.

What a helical tieback anchor in fact does

Despite the label, a helical tieback is certainly not a pile in the upright sense. Think of it as a steel tendon along with helical plates that screws flat or even at a superficial higher angle right into competent soil or even weathered stone, after that gets latched off to a wall, dragging, or even quality shaft. The helixes build central capacity by means of end-bearing as well as rubbing along bum rap. The "tieback" section is actually the strain occupied between the support head and also the assisted structure.

Unlike grouted rock anchors that require drill-and-grout patterns as well as remedying opportunity, a helical tieback provides prompt lots with torque-to-capacity relationship. With calibrated installment, you verify ability as you go. That proof is actually a significant main reason these supports have actually ended up being a staple in commercial foundation repair and also structural foundation repair where timetables are actually tight.

Situations that require helical tieback anchors

The clearest use instances discuss a pattern: lateral planet stress or hydrostatic pressures that exceed a design's resistance, but without room, budget plan, or even opportunity for primary excavation or cast-in-place countermeasures.

Retaining designs that can easily certainly not creep any kind of even more. We usually put in helical tiebacks on retaining walls adjacent to social rights-of-way, car parking decks, or even building pipes where digging would close down website traffic or breach easements. Tiebacks set up from the inside skin of the wall surface fix this properly. Design usually targets planet tension at-rest or even active-plus-surcharge, along with appropriate lots factors.

Basement as well as below-grade wall structures revealing internal displacement. Inclined or cropped CMU, broken cast-in-place wall structures, and spandrel ray of light trouble point to sidewise overload, not negotiation. Helical tieback installment by means of wall primaries, incorporated with interior walers or even platters, may stabilize the wall and, in many cases, recover a portion of deflection.

Temporary shoring for excavations as well as enhancements. For industrial expansions or utility passages, helical tieback anchors join soldier stacks or even piece piles to hold back cuts while groundworks are put in. Contractors choose them because there is no cement healing delay, as well as a small crew along with portable equipment can do work in tight urban lots.

Seawalls as well as waterfront bulkheads. Hardwood or steel bulkheads drop area eventually. Changing deadman anchors with helical anchors, frequently tilted to get to beneath dependable upland dirts, repairs capacity without shreding promenades or landscape design. Corrosion protection as well as appropriate hot-dip priming come to be crucial near saltwater.

Brick or even stone front stabilization over areaways and tunnels. In thick midtown corridors, spaces under sidewalks and superficial tunnels make complex excavation. Helical tiebacks may be cast to bypass deep spaces as well as lock into competent strata, then attached to a brand new lintel or even interior frame.

In each case, the market value hinges on propelling stress capability against side forces while maintaining disorder reduced. That is actually various coming from commercial helical pile installation or commercial resistance pile installation, which target upright load assistance. Helical tiebacks sustain wall surfaces and excavation devices; helical piles and resistance stacks support pillars, pieces, and grade beams.

When helical tiebacks are actually the wrong tool

They are certainly not a cure-all. Poor applicant ailments feature extremely heavy cobble levels that refuse penetration, extensive boulders, or even strongly corrosive grounds without an engineered rust program. If the wall surface is actually actually at the verge of crash with smashed units and inadequate diaphragm activity, tiebacks alone can easily certainly not wait; you might need to reconstruct and also include steel frames. Where vibration constraints are actually extreme, also the modest electricity from a drive electric motor could be a problem, although this is rare.

Where the design demands especially higher personal abilities, like singular anchors over 150 to 200 kips in pressure, micropiles along with housing and also grout bulb or punched rock supports may be even more economical per unit capacity. For short-term shoring where decommissioning will definitely be actually obligatory, ground nails or even grouted anchors can surpass in unit price, especially on huge repeated keep up straightforward access.

Reading the ground, not just the drawings

Most specifications focus on noticeable the planet tension diagrams as well as factored tons. Those concern, however results hangs on stratigraphy. Helical anchors require an experienced bearing coating for the helixes. In gentle clay-baseds, our experts upsize the coil size as well as enhance the amount of plates, yet the concept should still deliver adequate embedment beyond the energetic wedge. In sands, we expect liquefaction possibility and drain paths. In split accounts, it prevails to bypass a silty seam and try for the dense sand at 18 to 25 feets for trusted twist correlation.

On a healthcare facility redesign in antarctic till, we predrilled pilot gaps via a 6-foot cobble band to reach out to Great post to read the dense matrix listed below. Predrill does not neutralize capability if the coils still bite into untroubled product at the concept deepness, but it requires mindful twist monitoring and, occasionally, a modified Kt (the twist relationship continuous) based upon field proof tests.

How helical tiebacks compare to various other anchor and stack systems

Owners and also developers frequently talk to whether they need to use helical piles, resistance heaps, micropiles, or tieback anchors. The answer circulates coming from the load direction and also constructability constraints.

Commercial helical pile installment as well as resistance pile installment deal with vertical loads and also settlement deal control. Helical piles, along with their helical plates, master clay-baseds as well as blended dirts, can be installed with reduced sound and vibration, and also supply instant capacity. Resistance heaps, or press piles, build ability through mounting steel stacks against the structure, removing ground as opposed to eliminating it. They work for deriving when headroom is tight and also when the existing building can easily function as a response to steer the piles.

Micropiles, commonly steel canvassing with grouted centers, sparkle in very heavy soils or rock, along with high allowed bunches and also flexibility for both stress and also compression. Micropile installation requires exploration, encouragement, as well as grout healing, which boosts opportunity however supplies strong efficiency in difficult geology and also constricted sites. Micropiles can easily function as tiebacks with necessary style, often used when the demanded strain ability is actually past regular helical tieback ranges.

Helical tieback anchors being in the sidewise bunch edge. Where you require to pull back a wall surface or even keep an excavation without massive devices, they offer you verified, prompt stress capacity along with minimal spoils. They can easily enhance other deep foundation repair strategies: a wall structure stabilized along with tiebacks could rest atop a level beam supported by helical piles, resistance piles, or micropiles, each participating in an unique role.

The auto mechanics of style that matter in the field

The academic side recognizes: define the energetic wedge, administer planet stress coefficients, incorporate surcharges, include hydrostatic or even seismic elements, and then pick a tieback design as well as viewpoint. Virtual, a handful of particulars move the needle.

Embedment duration past the academic failing plane needs to have frame. Our company target 8 to twelve feet past the position in clay, occasionally more in sand to reach dense strata. The a greater distance the coils rest past the breakdown block, the less delicate they are to small inaccuracies in soil parameters.

Helix setup is actually not cosmetic. A two-helix anchor with 8 as well as 10 inch layers behaves differently than a three-helix with 10, 12, 14 inch layers. Plate spacing of 3 opportunities the dimension minimizes layer overlap in soils as well as raises web capability. In soft clay-baseds, larger sizes along with greater space carry out a lot better, however disk torque increases and set up equipment need to be actually sized accordingly.

Angle of setup and also bond duration positioning effect ability and functionality. Steeper slants reach much deeper faster however might clash with interior blockages. A flatter slant reduces crown height inside the property but stretches the support and also may call for a longer area past the failing plane. Stabilizing slant with web site geometry is actually part art, part math.

Corrosion protection can easily not be actually a second thought. For irreversible commercial foundation stabilization, we define hot-dip galvanizing, improved propitiatory thickness, and also in some cases a double-correlation strategy where foreseed reduction is evaluated over fifty to 75 years. In very aggressive grounds, utilizing epoxy-coated parts or embedded rays with grout-filled sleeves may be justified.

Load confirmation belongs on the essential pathway. Install torque is actually a stand-in, not a warranty. Verification examinations on a minimum of 5 per-cent of anchors, and efficiency examinations on decided on sites, decrease risk. If action under proof load exceeds requirements, tighten the design prior to production continues.

Installation facts that split excellent from great

Commercial helical tieback anchor installment unfolds virtually the same way whenever, however the end results vary widely relying on team experience as well as the quality of layout.

Access and targeting are the initial constraints. Inside a basement, you typically work under ray of lights, around mechanicals, and via masonry centers. Our company prepare core locations to stay away from rebar or bond beam of lights, make use of a scanning device to map steel, and established walers ahead of drilling to regulate alignment.

Torque monitoring have to be disciplined. Utilize an adjusted electronic torque display and log analyses at each feet of seepage. An unexpected torque spike can signal a cobble; a plateau in sand may suggest small failure around bum rap. The lead installer creates real-time telephone calls: back out somewhat, readjust helical pile foundations velocity, or even swap to a distinct coil configuration if you are not accomplishing the awaited twist at concept depth.

Grouting is not always component of helical anchor work, but some specifications ask for post-grout to strengthen capacity in granular soils. When utilized, low-mobility cement pushed at the helix elevation may lock in performance. The trade-off is actually opportunity and clean-up.

Head particulars are where aesthetic appeals and also maintenance intersect. On left open indoor walls, our company use low-profile platters or include the support head in to a steel waler repainted to match. On outdoor preserving wall structures, we aim to recess platters responsible for a brand new veneer or capstone to keep the support hardware hidden as well as out of straight water exposure.

Coordination along with other deep foundation repair trades matters. If the task also includes commercial helical pile installation for brand-new pillars or even commercial micro pile installation under a piece, lay out the anchor follower styles initially to steer clear of clashes. It is actually less complicated to switch a heap location just before drilling than to reroute a line of tiebacks that presently pass through the wall.

A practical check out capability and also movement

Owners in some cases count on zero action under bunch. That is certainly not just how soil-structure bodies behave. A helical tieback anchor possesses elastic prolongation under tension, plus slight seats of layers and compressibility of the dirt mass. In a typical cellar wall surface retrofit, expect a handful of millimeters of draw at verification weight, and also possibly 1 to 3 millimeters a lot more throughout lock-off as the wall surface starts to discuss weight. Those varieties are actually certainly not failings; they reflect physics.

If you are actually attempting to take an inclined wall back to plumb, take care. Drawing also hard in round can break down breakable stonework or even shear anchors at the head. Our team organize loads all over support lines and screen gap evaluates. Sometimes the most effective result is actually stabilization at the present line, along with cosmetics handled through epoxy shot or even brickwork fixings. For foundation crack repair, tiebacks quit the cause of motion; they do certainly not "cure" gaps. You still need to have to resolve water control, repointing, or epoxy and also carbon fiber where appropriate.

Permitting, electricals, and also risk

Do not bypass power situates inside and also outside. Also inside a basement, avenues can manage in wall surfaces and pieces. In older structures, as-built illustrations are confident myth. A non-destructive check and a mindful fly gap technique save frustrations. For outside tiebacks crossing feature series, safe and secure easements or even make use of infringement agreements. Many legal systems manage tiebacks beneath social rights-of-way as infringements that call for removable supports or exclusive permits.

Seismic zones bring extra examinations. Tiebacks can be aspect of a general seismic conditioning deal, yet design needs to look at periodic payload effects and also possible reduction of passive stress throughout trembling. In saturated sands, loss of side protection in the course of an event may justify much deeper embedment as well as repetitive rows.

Cost as well as routine expectations

Compared to drilled anchors, helical tiebacks typically reduced times off the schedule since there is no grout remedy opportunity prior to load screening and lock-off. In uncomplicated dirts, a two-person workers along with the right travel scalp may install several anchors each day, more if gain access to is excellent and also embedment is actually superficial. Costs differ extensively through area and specification, but on commercial tasks the device cost lands positively when capacity requirements are in the twenty to 80 kip variation per support as well as internet site strategies are actually tight.

When ability needs increase or soils fight penetration, micropiles or grouted anchors may mesmerize in cost-effectiveness. A blended technique is common: helical tiebacks where gain access to is actually tight and bunches are moderate, micropiles where the lots are actually high or geography is difficult, and helical piles or even protection stacks for upright assistance. That equilibrium always keeps finances logical while complying with design criteria.

Case snapshots from the field

Parking garage maintaining wall structure, downtown infill. The wall bulged 1.5 ins at midheight on the lowest amount. Digging outside the building line was actually difficult. Our team cored at staggered elevations, installed helical tiebacks at a 15 degree upwards angle to get to dense sand at 22 feets, as well as locked off to a steel waler covering pillar to column. Verification exams at 1.5 times concept lots stabilized within 0.08 ins. The manager reopened gulfs within the week.

Bulkhead rehabilitation at a harbor. Wood deadman supports were actually decayed in saltwater splash areas. Our team used hot-dip driven helical anchors along with lengthy sacrificial thickness, put in coming from the dock deck at a shallow angle to reach upland grounds. A continuous hat network spread tons. Regular torque spikes signified buried clutter; our company adjusted paths and chronicled torque completely. The port got an additional many years of service lifestyle along with low interruption to tenants.

Historic cellar along with rock debris walls. The wall structures had uneven skins as well as lime mortar. Tieback heads required creative bearing. Our team mounted steel walers shimmed to the masonry, firmed up in phases to prevent coming stones, and incorporated interior steel posts under shafts sustained by helical piles. The combination of helical tiebacks and also helical piles offered the manager both side as well as upright stabilization without invasive excavation.

Integrating tiebacks in to a thorough repair plan

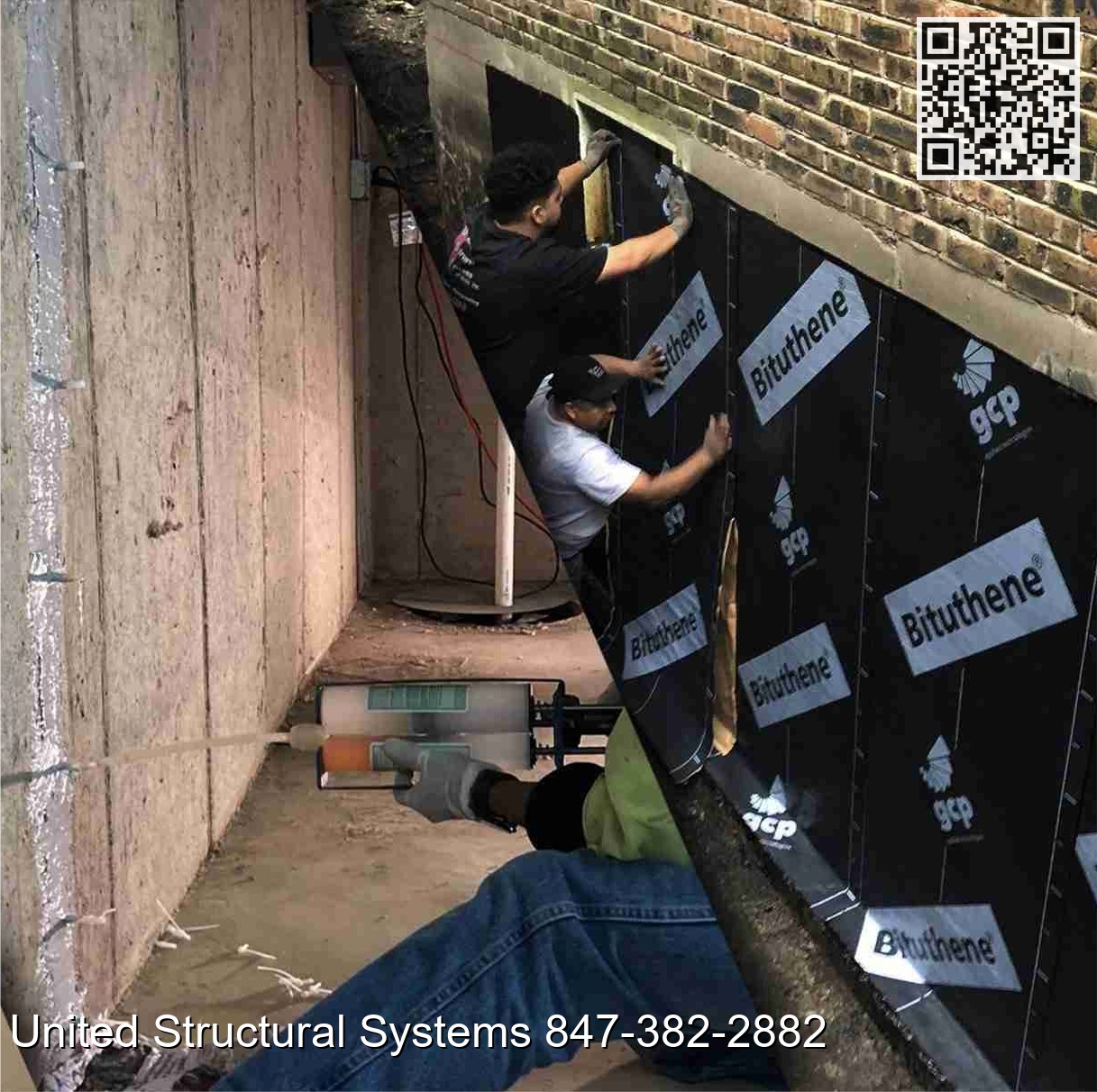

A successful commercial foundation stabilization plan looks beyond one item. Side restraint coming from tiebacks pairs typically along with drain remodelings to lower hydrostatic stress. Water is actually unforgiving: if your wall structure sees groundwater, include border empties, septic tank redundancy, and water-proofing membrane layers. Inside, address structural constancy. A tieback secured into a cracked wall without waler or even diaphragm support may center stress and also lead to breakable failure.

For jobs along with resolution as well as lateral problems, make use of the appropriate mix. A quality beam supported through helical piles or resistance stacks deals with vertical loads and stops additional settlement deal. Helical tiebacks take care of sidewise pressure. If tons surpass normal helical assortments or geography directs, integrate micropiles or even grouted supports. The goal is certainly not to promote one technology, but to meet the structure's demands along with a coordinated system.

Practical list for opting for helical tiebacks

- The driving complication is actually sidewise motion, not vertical settlement deal, and also excavation is actually constrained by powers, residential property lines, or social access. Subsurface examination recognizes a proficient bearing coating obtainable along with coils at acceptable torque, beyond the energetic breakdown plane. Required working loads per anchor fit within traditional helical tieback capability ranges for on call equipment and also staff skills. The task benefits from immediate bunch proof as well as sped up schedule compared to grouted systems. Corrosion health conditions are know, and the layout features ideal protection for the wanted service life.

A word on guarantees and also documentation

Owners respect guarantees. Deal guarantees you can easily recognize by controlling variables. Calibrate twist devices, file setup records, keep evidence examination records, and also photograph head details before they fade away responsible for coatings. Where supports cross into public or neighboring residential property, maintain signed easements along with the task document. For structural foundation repair, that proof often becomes as valuable as the steel itself when the structure modifications hands.

Where foundation crack repair fits

Tiebacks perform certainly not shut gaps, but they cease the lots that created them. After stabilization, epoxy shot can repair big habits in cement wall structures if splits are actually completely dry and tidy. In masonry, sewing with helical bars set in cement, combined along with repointing, supplies continuity. When splits are actually steered through hydrostatic stress, add internal water drainage and also exterior basement waterproofing where feasible. It is common to stage this pattern: maintain along with tiebacks, deal with water, then restore gaps. That order lowers the possibility of re-cracking.

Final notions coming from the field

If the task inquires you to hold back dirt, water, or a framework that would rather move sidewards, helical tieback anchors should have an early appeal. They deliver predictable capacity, rate, and a little jobsite footprint. They incorporate well along with other factors of deep foundation repair, featuring helical piles, protection piles, and also micropiles, each packing its street. Their constraints are actually as essential as their toughness: geology, oxidation, and ability targets need to align. When they do, the outcome is tiring in the most effective method, a wall structure that stays and a client that overlooks you were actually ever there.