Speed is actually seldom almost the clock on a wall. On a commercial internet site, installment time translates to lane-closure licenses, crane rentals, staff overtime, sound home windows, groundwater monitoring, as well as the real amount that matters: times till the superstructure or even fixing can continue. When managers talk to which unit puts in faster, helical piles or driven protection stacks, the sincere solution is actually, "It relies," however not in a hand-wavy way. Ground stratigraphy, get access to, mobilization footprint, and bunch account turn the ranges, occasionally greatly. If your objective is trimming days, or perhaps hrs, from a schedule without sacrificing capability or even observance, you need to contrast the procedure actions alongside as well as in the field disorders you actually have.

I have actually spent enough opportunity around rigs, torque monitors, and also assessors to understand that headline speeds commonly hide the sluggish parts, like relocating equipment via a real-time building or waiting on delivery of the best extensions. The particulars under show that lived truth, certainly not a manufacturer's brochure.

What "rate" actually indicates in the field

Installation rate shows up in 4 spots. First, mobilization: the moment to receive workers, materials, as well as equipment to the place where the first stack begins. Second, creation price: the amount of stacks per change your workers completes in the dirt you possess, to the depths you in fact need to have. Third, disturbances: evaluations, screening, sound constraints, or wreckages that stop work. 4th, demobilization and handoff: cleanup, proof testing documentation, and the second the building may depend on the mounted system.

Helical stacks as well as steered resistance stacks take care of these phases differently. Helicals are torque-installed using gas travels as well as somewhat small equipment, while resistance piles are actually usually steered with a hydraulic ram reacting versus the existing construct or even a temporary frame, seating components up until defined ability is actually accomplished by drive tension or even collection. Each approaches are common in commercial foundation repair as well as in commercial foundation stabilization for brand new as well as existing structures.

How helical piles go into the ground

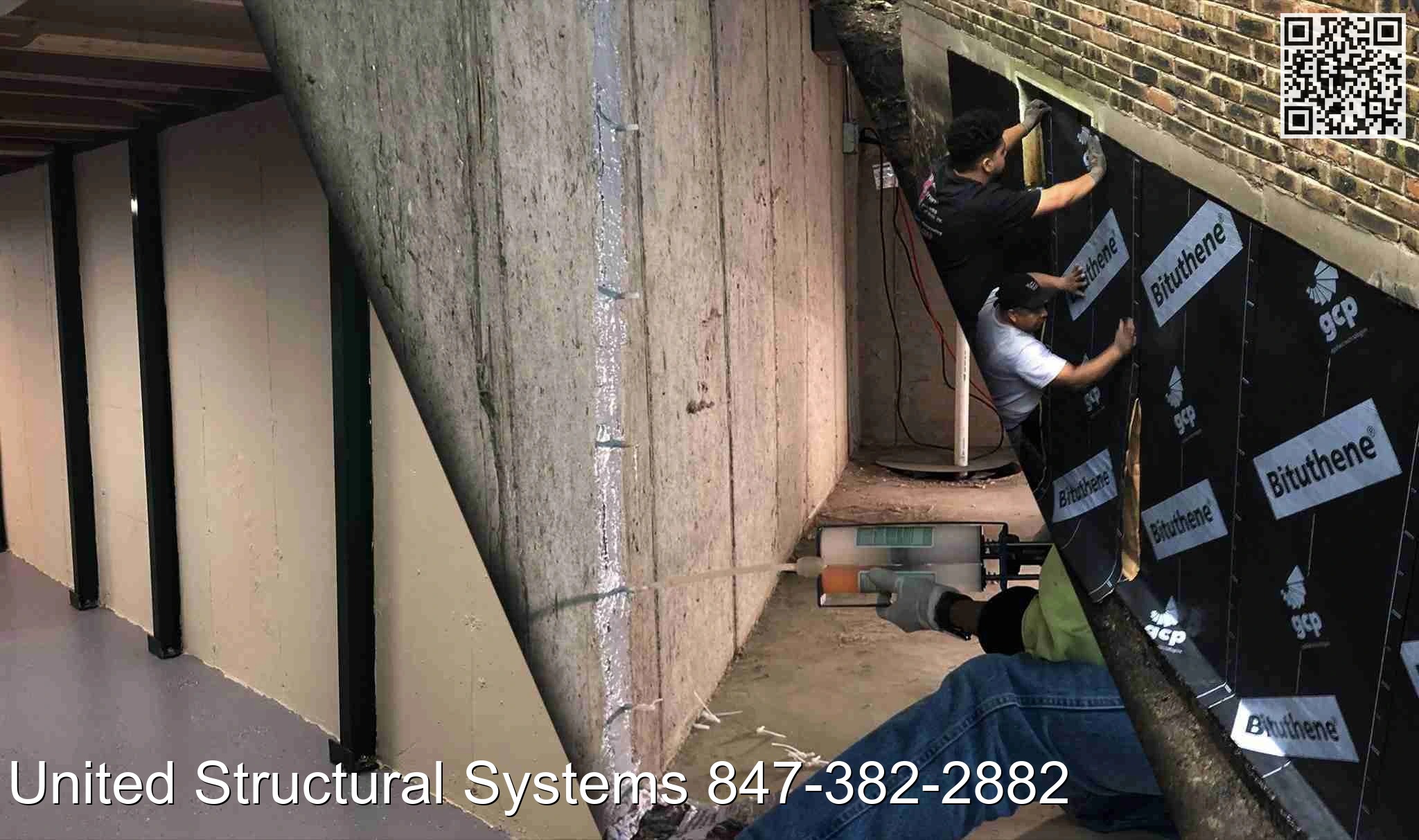

A helical pile makes use of several helical layers welded to a main ray. You rotate it in to the dirt, progressing the coil much like a screw. In commercial helical pile installation, the team typically makes use of a skid steer, mini-excavator, or even sleek excavator along with a high-torque drive head. You track torque continuously to estimate ability. The moment you reach target torque at intensity, you cancel with a new-construction limit or even underpinning bracket. For sidewise or uplift needs, you could add helical anchors or helical tieback anchors, set up likewise however angled and anchored in to additional capable soil. For keeping wall structures or cellar wall structures, commercial helical tieback anchor installation regularly couple with shotcrete or soldier piles.

From a rate viewpoint, the simple advantage is turning over impact. You don't need heavy impact hammers, you commonly stay clear of pre-drilling, and you can work in strict inner parts where elevation is restricted. On a solitary shift with reasonable soils, an experienced two to three individual staff typically establishes 8 to 20 helical piles, with outliers much higher when whatever clicks on. Quick operates under a hundred stacks see the absolute most significant perk because use is mild. For deep foundation repair in active buildings, helicals could be set up along with minimal resonance, lessening coordination along with delicate tenants.

How steered protection heaps are installed

The steered resistance pile, in some cases phoned a push boat dock or protection boat dock, is a compression-only unit very most largely made use of for structural foundation repair. You specified a brace at the footing, then drive steel pipeline sections along with a hydraulic ram, making use of the body weight of the framework as reaction. You drive segments up until intended stress is actually gotten to or you hit rejection. As soon as all heaps under a ground get to the prescribed worth, you can elevate if concept calls for it and also lock off.

The velocity of commercial resistance pile installation can be excellent when the structure supplies really good response and also dirt is consistent. While mobilization may be also lighter than helicals in an underpinning situation, the development fee can easily differ more due to the fact that each pier depends on real building weight and the particular ground layer sequence. If you must add temporary response structures or if grounds are actually uneven, speed drops. In wide-open new building and construction, resistance piles are actually less popular than helical piles or micropiles, but on repair service projects they are actually staples given that capability verification is quick through drive pressure.

Measuring the time clock: traditional production ranges

Tie speed to practical amounts as opposed to best-case tales, and also designs seem. In silty sands or strong clay-baseds with reduced fragments, a helical setup can easily accelerate at approximately 1 to 3 minutes every feet once the travel head is interacted, certainly not counting alignment or combining. Depths of 20 to 40 feets are common in lots of business setups, which puts a singular heap at 30 to 90 mins if every little thing goes easily. On a web site along with unobstructed accessibility as well as modest torque criteria, a workers may commonly accomplish 10 to 16 helical turn in a common time. Add tough levels, cobbles, or rubbish fill as well as the cost can fall to 4 to 8 every day because of pin shears, re-drives, or even changing to bigger helices.

Driven resistance stacks usually relocate faster when the structure supplies a powerful response. In deriving mode, driving 20 to 40 feets can easily take 15 to 45 minutes per location, once more leaving out brace prep work, which is the slow-moving component. If footings are actually well-maintained, consistent, as well as available, as well as if no short-term shoring is needed, it is actually realistic to attack 6 to 12 boat docks every day with a small staff. The spread is actually broad considering that footing preparation may multiply or even three-way time if cement requirements coring or even if reinforcement conflicts. If you acquire a "brick wall structure" at 8 feet and also need to have to switch systems or pre-drill, the whole time can skew.

For evaluation, micropiles take up a 3rd street. Micropile installation entails punching a tiny size shaft, positioning steel, and grouting. Manufacturing can be stable in extremely thick city sites where driven choices will be constricted by sound or even resonance. In return for broad relevancy, micropiles sacrifice raw speed every opening. Anticipate 2 to 6 each day depending upon diameter, exploration approach, as well as subsurface health conditions. On jobs where commercial micro pile installation brings the lots as a result of reduced space or even blockages, schedule assurance usually hammers speed.

Mobilization and also setup time

Equipment selection specifies the shade. For commercial helical pile installation, activating a small excavator with a 10 to twenty thousand foot-pound ride head, twist surveillance, and also a truck with pile segments is simple. You may present within a few garage. For interiors, you spin the ride scalp through dual doors, occasionally partly, and rebuild within. You require space identical to the lengthiest area you consider to install, commonly 5 to 7 feets for fractional shafts. Marginal internet site prep means your very first creation stack may begin within hrs of arrival.

With protection piles, the lightest pathway exists when founding. You require braces, gas rams, pipes, a pump, and steel segments. You also need to have footing access, which suggests digging at each boat dock location, sometimes found reducing pieces, and also cleansing the footing bottom. That prep stage can eat half the day on the very first few sites. In favorable situations, however, once the bracket is established, driving is brisk. The rate concern depends upon exactly how repeated the ground particular is actually. If all grounds suit, create ends up being production line work.

Noise, resonance, as well as work windows

On medical centers, records centers, and filled workplaces, sound home windows as well as resonance limitations determine installment rhythm. Helical piles are actually silent. You listen to the gas drive and also soil rubbing, certainly not pound strikes. This usually means longer constant job home windows as well as far fewer disturbances, which raises effective speed even if pure production rates are similar. Resistance stacks produce more sound throughout footing preparation than throughout steering, given that the gas port is actually rather quiet. In vibration-sensitive environments, both systems outshine impact-driven heaps and lots of drilling approaches, yet helicals often gain fewer sound complaints.

Access and also space constraints

In basements, tunnel-adjacent job, or even retail fit-outs, space eliminates rate. Helical units adapt properly with brief sections as well as right-angle rides. You can easily put in helical tieback anchors via a coring sleeve inside a strict mechanical space, functioning around ductworks and also lines. Resistance heaps also polish in reduced headroom given that portions are short as well as the port sits at the footing. The decider becomes geometry: helicals need rotational allowance, resistance piles need brace open space. In my experience, helicals relocate much faster where space is tight yet sensibly open around the heap place, while protection stacks succeed when the footing is the only available surface and also you may excavate straight under it.

Soil disorders that speed up or stall each method

Soil controls creation, capability correlation, and team well-being. Helical piles like even, fine-grained dirts and also stiff clays. They loathe sizable cobbles, entraped building and construction debris, and very smooth natural layers where twist surges yet overlays perform certainly not "bite" properly. Pre-drilling is an option yet neutralizes some speed conveniences. In sands along with higher groundwater, torque relationship continues to be strong, and the method stays tidy matched up to slurry drilling.

Resistance heaps favor profiles where end bearing or friction constructs gradually as well as the establishment uses adequate response to steer to design tensions. They battle in incredibly light properties where you may not produce adequate reaction to breakthrough piles. In those scenarios, a short-lived response framework adds expense and also time. They likewise decrease when you run into differing layers under neighboring braces, due to the fact that every area develops into its very own investigation.

Micropiles take care of very most unpleasant ground however at the expense of velocity. If your site consists of rubble fill or karst voids, micropiles provide assurance through boring and also grouting via it, which can easily stabilize a routine that will otherwise be unpredictable with steered systems.

Quality control and proof of capacity

Helicals deliver torque-to-capacity connection. A lot of engineers use established connections alongside site-specific calibration if needed. Torque surveillance is ongoing, logged, and basic to evaluate. From a velocity perspective, that implies ability verification happens in the course of improvement, and also you do certainly not expect cement to heal or cylinders to arrive. For commercial foundation stabilization under opportunity pressure, that is actually a huge plus.

Resistance piles prove capability by drive pressure as well as collection, which the inspector can witness and also log in real time. Proof and also lift frequently take place the exact same day, speeding structural foundation repair. The pause arrives when footing variability or eccentric bunches demand re-checks or added heaps, which you find one bracket each time. Helicals often tend to disclose problems previously via twist trends.

Micropiles require cement treatment and, if pointed out, lots examinations that happen after a standing by time frame. On lengthy routines or multi-phase building, that is actually convenient. On an emergency situation commercial foundation repair where a pillar needs to have to become back online tomorrow, micropiles rarely contend on speed.

Case sketches that uncover the trade-offs

An office build-out in a midtown tower needed to switch out a line of columns along with a transmission beam, demanding brand new deep-seated supports in a garage with 9-foot headroom and strict noise limits. Helical piles hit 35 feet through filler into thick sand. Two drivers and also a worker mounted 12 piles over 2 days, including layout, torque monitoring, and also caps. A driven option would certainly require pre-drilling through floor beams to acquire response or even short-term structures, adding a time or two.

A big-box retail negotiation fixing used protection piles due to the fact that the slab and footings were accessible and also consistent. Footing bases were actually clean, the structure held really good body weight, and also dirt was actually a foreseeable silty clay-based. Two staffs balanced 10 to 14 boat docks per day, raising parts as they went, as well as debated regions to floor service providers in turn. Helicals would possess operated, yet brace prepare was the pacing product regardless, and also resistance stacks possessed lower components price every location.

A lighting creating resource on really soft alluvial dirts preferred helical piles for new equipment pads. The building's body weight will not have actually given ample response for resistance piles in the course of installment, and brief structures will have slowed down points down. helical pile foundation applications Helicals hit layout torque at 42 feets with 8-inch and also 10-inch layers, and the crew kept a steady rhythm, 9 to 11 piles every day per gear, in spite of small torque delays around stashed debris.

Tiebacks as well as anchors: schedule take advantage of on sidewise work

For keeping constructs and cellar wall surfaces, helical tieback anchors increase routines given that you can easily examine them immediately to make lots and also move to the next area. No grout cure, low wreck. On a shotcrete soldier heap wall surface along a home line, our team provided tiebacks at 15 to 25 minutes each in medium rich sands, tested right away, and trimmed down to duration. Typical grouted tieback anchors would have compelled a multi-day lag between drill, grout, and test, crowding the wall with business as well as slowing rebar and shotcrete crews.

That stated, if geology is fractured rock or strongly changeable, grouted tiebacks might outmatch helicals simply by piercing through the trouble levels with confidence. As constantly, speed complies with predictability.

Logistics that quietly decide outcomes

Crews shed velocity at couplings and also in setting up. Along with helicals, prepare your extension mix to minimize joints: excessive quick sticks spare space yet burn time. Always keep a clean laydown, power source within tube length, and spare nail down standby. Watch on twist calibration, given that a dead transducer stops a task faster than anything.

Resistance stack teams gain time by systematizing brace preparation. Saws and also chipping guns presented every place, templates for bolt holes, and pre-cut shims create the difference between 30 minutes and 90 minutes. If you need to have to relocate spoil or even work in slender troughs, schedule a committed laborer to keep the pile top clear so the jack driver certainly never waits.

For commercial helical pile installation as well as commercial resistance pile installation in urban sites, deliveries should unite along with the work front. Twenty minutes waiting on a forklift 5 opportunities a time gets rid of the theoretical velocity perk of any kind of system.

Where price converges with speed

Projects seldom spend for rate alone. If products for helicals set you back more than push piers, or the other way around, a timetable win need to offset dollars. The fastest mount can easily shed to a slightly slower method if workers dimension is actually leaner or if you can run two much smaller gears in parallel instead of one bigger unit along with an abandoned second workers. Micropiles, although slower every location, might enable night job when raucous choices are banned, which may squeeze calendar days sufficient to win.

The right metric is actually frequently heaps per crew-day per dollar of all-in price. Helicals excel at mild matters with tough access. Resistance stacks stand out at recurring reinforcement on bigger structures. Micropiles stand out at complex geology or even quite tight hallways with foreseeable, if slower, progress.

Foundation split repair work as well as the clock

Crack fixing in commercial setups usually couple with deep-seated aspects. If a wall surface shows stair-step gaps tied to negotiation, your timetable depends upon stabilizing movement just before epoxy injection or even carbon fiber job. Helical piles under complication footings can arrest movement promptly, and also helical tiebacks can alleviate side loads responsible for a stooping wall to ensure gap fixings hold. Resistance piles can possibly do the exact same in squeezing zones. The installation approach you choose directs when you can properly infuse, spot, and reopen the room. A time or 2 conserved deep foundation repair often saves a full week of follow-on business, which is actually why superintendents stress over the pile calendar.

Practical assistance for opting for velocity on your project

- If space is restricted, sound is actually limited, and ground is fairly steady, helicals commonly supply the quickest road to capability along with minimal disruption. If you are founding much heavier office grounds with excellent accessibility and uniform information, protection stacks commonly outpace helicals once footing prepare is actually streamlined. If geography is actually unfavorable to steered devices or even get access to is severe, micropiles may move slower per hole yet keep the timetable predictable as well as crews productive. For lateral or uplift necessities against cramping timetables, helical anchors as well as helical tieback anchors stay away from cement remedy and allow prompt verification testing. When a structure is actually as well lightweight to respond for protection piles, count on problems coming from short-term frames. Helicals sidestep that, which often creates all of them much faster even with identical per-pile times.

A better examine team structure as well as productivity

On a typical helical crew, you possess an operator on the bulldozer or skid, a top for positioning and also twist surveillance, as well as a worker managing extensions and also pins. With good rhythm, the operator certainly never leaves behind the commands. The twist lead places centerline as well as examinations plumb, and the worker nourishes the next piece. Any time the operator walk out to assist with combinings, creation drops. Small tweaks, like pre-lubed screws and also a shadow board for wrenches, maintain movement fluid.

For resistance heaps, the brace crew does the massive training. The operator deals with digging and also footing prep. The port operator as well as a 2nd laborer travel portions, keep track of stress, and weld or pin joints as needed to have. Since each place possesses its own mini-sequence, instruction for repeatable bracket create and constant bearing surface finish is actually the largest lever on velocity. Workers that photo and also record each brace before steering catch mistakes early and also steer clear of remodel that burns half-days.

Documentation and also turn over without dropping time

Inspectors love records greater than your stopwatch, and rightfully so. For helical piles, clean twist records along with deepness versus twist charts, stack ID, and firing details let the developer accept the very same time. For protection stacks, drive pressure logs every assist, brace IDs, and also lift records support acceptance. Create layouts for each. When commercial foundation repair includes loads of indoor stacks inside an operating resource, paperwork delays can easily slow follow-on exchanges even when the piles entered fast.

The role of concept choices in industry speed

Design is certainly not neutral to accelerate. A helical style that utilizes a slightly much larger helix to cut deepness by 10 feets might save a time throughout lots of heaps. A protection pier format that merges areas right into balanced teams can reduce lift patterns as well as lower the lot of uses. On micropiles, choosing an examining with the leading rubble zone avoids stuck rods as well as shed tooling, keeping drilling continual. Developers and service providers who work together early can trade tiny component increases for big schedule gains.

Where the 2 devices comply with in crossbreed solutions

Plenty of commercial tasks gain from mixing systems. Helicals can easily take care of internal pillars where gain access to is actually tough, while protection stacks assist perimeter footings along with much better excavation gain access to. Helical tiebacks can easily take care of lateral tons on a wall surface while micropiles take vertical tons at the exact same soldier stacks. The fastest overall timetable sometimes comes from utilizing each device where it runs better, rather than pushing one technique to carry out everything.

Bottom line for schedulers and owners

If installation velocity is actually the concern, helical piles normally lead on tasks along with limited access, rigorous noise restrictions, or changeable work home windows. Resistance stacks frequently bait repetitive underpinning under bigger industrial constructs where bracket prepare could be standard. Micropiles offer schedule certainty in difficult ground at the expense of slower per-hole opportunities. For lots of commercial foundation stabilization tasks, the fastest finish pairs helicals for upright loads along with helical tieback anchors for sidewise control, handing off to split repair work and skyscraper job without a remedy delay.

The most intelligent approach is actually to simulated up a couple of sites early. Track actual moments for every action, certainly not simply the drilling or steering. Action brace prep, combining time, verification, and cleaning. Make use of that information to project your crew-day matter. With straightforward amounts, the choice in between a helical pile as well as a resistance pile penetrates, and the days you save will certainly turn up not just in the stack log yet in the crucial path that matters to every person on site.